Pallet rack supports and wire decking are two common options used to better distribute and support the weight of pallets on pallet rack beams. You may be wondering whether it is even necessary to purchase one of these options as pallet rack on its own can support the weight of pallets. Yes, pallet racks are strong enough to support the weight of pallets, and in an ideal world, we would only have undamaged pallets that are well balanced and fit on top of your pallet rack beams perfectly. But unfortunately, you probably have a lot of pallets that are not quite large enough to balance on the beams, or have been damaged and are not very stable. In this case, additional support can help reinforce your pallet rack, prevent product damage and potential injuries.

What are Pallet Rack Supports?

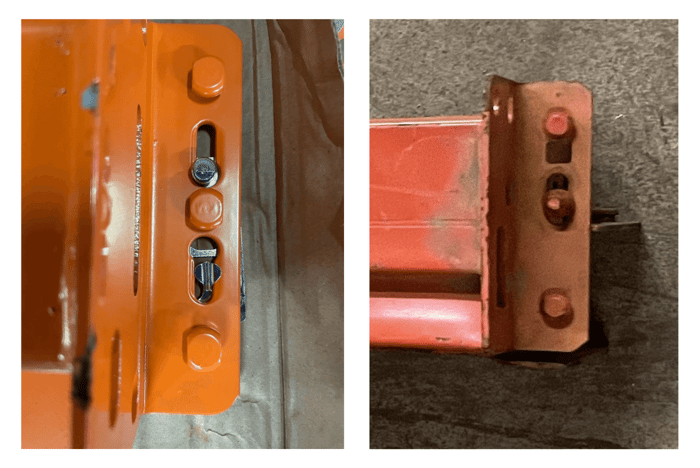

Pallet rack supports are installed directly onto the pallet rack beams and create vertical bars across the beam to support the bottom of a pallet. They are usually designed to sit inside the step of the beam. They increase stability by adding more surface area for the pallet to sit on. Pallet rack supports also help balance pallets that are not distributed equally or are too short to sit directly on the beams.

A typical pallet support setup requires two supports per pallet position, the setup pictured above is using four per position.

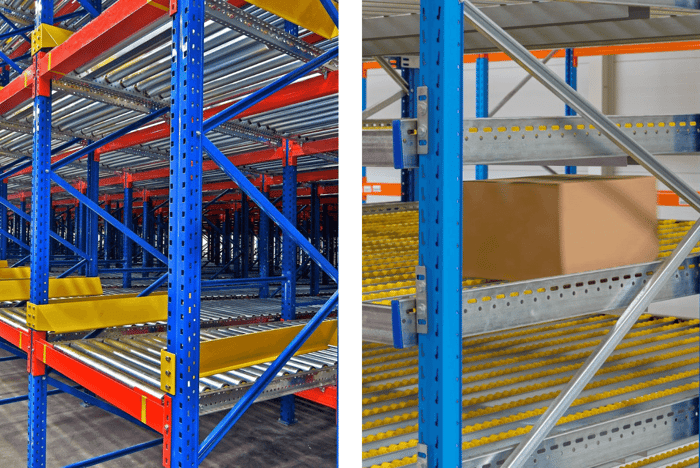

What is Wire Decking?

Wire decking is essentially a sheet of wire mesh that is designed to fit securely between the front and rear rack beams. Wire decking can support the weight of pallets and is also great for storing split cases and open cases. It also creates a wider surface area for pallets or products to sit on.

Pallet Rack Supports vs Wire Decking Comparison

Although these products are used for a similar purpose, they each have their advantages and disadvantages. We’ll next compare them across several criteria:

Meeting Codes

Let's start off by discussing whether or not you are required to use one product over the other. There are no specific codes requiring a warehouse or distribution center to use one product over the other, except in situations in which someone might be walking underneath the structure. In this case, utilizing wire decking is required as it will keep product from accidentally falling through and hitting the person walking underneath.

That said, it is very common for city fire codes that explicitly prevent the use of particle board when your pallet rack system is over 12' high. This is because the particleboard is both flammable and blocks overhead sprinklers from putting out a fire further down in the pallet rack system.

Use

Wire decking is great for also storing cartons, while pallet supports are made only for pallets to sit on. For this reason, wire decking is a little more versatile. For warehouses that may have changes to inventory, or frequently use open and split cases, wire decking may be a better option.

Safety

Both pallet rack supports and wire decking provide adequate support of the weight of pallets. As mentioned earlier, wire decking provides additional security preventing items from falling through. Waterfall-style wire decking also has a lip that provides additional support against dislodging. With proper installation, pallet rack supports can provide equal stability.

Cost

Pallet supports are a little more economical than wire decking, but not by much. Pallet support runs around $15-20/pallet, while wire decking is around $12-18/pallet. A great way to save money is purchasing used pallet supports.

Ease of Installation

Both of these types of support are fairly easy to install, but pallet supports require more labor to install as they will need to be screwed in to ensure that they don’t move. As far as the size options, they both come in standard sizes to fit 36”, 42”, 47” deep teardrop pallet rack and are meant to support a 2,500 lbs pallet. They can also both be custom ordered to support heavier pallets, and work with pallet rack uprights that are not the standard depth.

Pallet rack supports and wire decking are both good options for supporting pallets. They both have their use in the warehouse and the best option will depend on the needs of your operation. While there is no clear winner, we sell a lot more wire decking than we do pallet supports. We believe this is likely because: (a) wire decking is much more user-friendly, (b) wire decking provides better fall protection, and (c) the material is roughly the same price. Still not sure what you need? Talk to one of our Warehouse Consultants over the phone at 866-369-6178 or via email at sales@aslmhc.com.

$21.95

High strength pallet rack wire decking that works with any beam that has a 1-5/8" step. 3,820 lb capacity per deck Painted grey Double-sided outside waterfall ensures secure attachment Fits any style beam with a 1-5/8" inside step Sold individually… read moreNew Wire Deck, 24"D x 46"W, 1-5/8" STEP, 3 CHANNELS, DOUBLE OUTSIDE WATERFALL, GRAY, 3820# CAP

About American Storage and Logistics

Founded in 1958 to provide pallet rack to local distribution centers, ASL has evolved to offer complete turnkey warehouse solutions from design to installation and teardown. Whether you require a new pallet rack layout, warehouse mezzanine system, or are simply looking to reconfigure your current setup, ASL offers the materials and services needed to make warehousing easy. You may find our entire inventory on our website.