If you are thinking about buying a pallet racking system, you should know that there’s more to them than just holding pallets. Pallet rack installation can be a complicated process. Then once the system is operational, you’ll want to provide regular maintenance and repair to your pallet rack as it absorbs wear and tear from the harsh environment inside your warehouse.

Here’s an overview of some critical things to think about as you develop a plan for pallet rack installation and maintenance. These tips should help you get the best ROI on your investment.

The basic pallet rack system

A pallet rack system is made up of seven key components. We think of it as your basic pallet rack system, but it’s known technically as a selective rack system. On selective racks, every pallet position is available to your forklift operator all the time. That’s not the case with more dense types of rack.

So if you’ll be buying a basic pallet rack system (or selective rack), you’ll want to get these components:

-

Uprights

-

Beams

-

Wire decking (or pallet supports)

-

Row spacers

-

Concrete anchors

-

Post protectors

-

Rack safety back panels

NEW TEARDROP BEAM, 4-5/8"H x 108"W, ORANGE, 16ga, 5441# CAP/PAIR

$38.08

Add to an existing system or pair with additional beams, wire decking and uprights to make your own custom pallet rack system. A typical setup requires two beams and two wire decks to create a shelf level. 4-5/8"H face with 5441# capacity… read more

Pallet Rack Installation

How to Determine the Needs of your System

Before you purchase your pallet rack system, make sure to come up with an efficient design that will fit your space and satisfy your business needs for years to come. It is recommended to get help from a professional when designing your pallet rack system. However, it is important for you to be educated about how to maximize your space and get the most out of your racking system while improving the efficiency of your operation. This process requires some thought about your business operation, the space where the shelving will be installed, and your products.

Layout

First, you’ll need to figure out where the pallet rack will be installed. Make sure to follow manufacturer’s guidelines on where to install the racking. For example, manufacturers recommend that pallet rack is installed on concrete floor.

Pallet rack is often arranged in aisles and rows to maximize space and allow access from both sides. Determine the length of each row, the width of the aisles, the space between each aisle, and your ceiling height. The aisle space depends on the size of your products and the equipment you use to access them. Also, consider how many people will need access to products at the same time and whether you need to leave extra space for that.

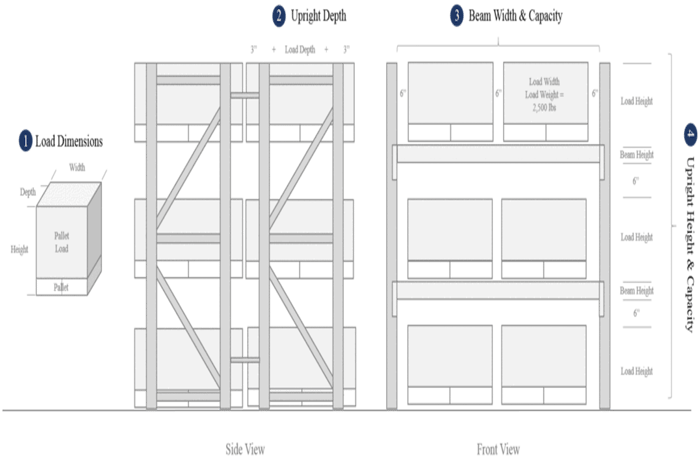

Capacity

Consider the type of products your racking system will hold. The size and type of your pallets, number of pallets per shelf, load size, and the maximum and average load weight should all be taken into account. Make sure to note any obstructions in your space when ordering uprights. Based on the products that you will store, there are different pallet rack accessories that can help you customize your system.

In-house team, outsourced vendor, or DIY Installation?

All pallet rack manufacturers strongly recommend that rack systems be assembled by professionals with prior experience. Normally, that should be the vendor you bought the rack from or an outsourced third-party installation team they recommend. The experience a professional installer has brings a high probability that the racks will be installed correctly and efficiently. This is important because improperly installing your pallet rack can void the warranty and is a major cause of pallet rack system failures.

If you decide your layout is small enough or simple enough to install on your own, you’ll want to keep the following in mind.

Before doing anything, inspect the rack you received for damage and inventory the materials to ensure they match your packing list. Once you know you have everything, you’ll want to read all the various manufacturer’s instructions and review the installation diagram or warehouse design layout (if applicable).

There are typically a few manufacturers involved in any pallet rack system and you’ll want to take a minute to read all the various installation instructions prior to beginning.

-

Concrete anchor manufacturer’s installation instructions for slab drilling, hole cleaning, and anchor installation

-

Project Manager or Engineer’s drawings

-

Pallet rack manufacturer’s instructions for assembling selective pallet rack

Once you’ve done all that you can begin the installation.

Pallet Rack Installation Steps

Tools You Will Need:

-

Tape measure

-

Chalk line

-

Lifting Device

-

Level

-

Mallet

Step 1: Start off by laying the rack footprint on the floor. To do this, snap a down-aisle chalk line defining the main aisle and snap cross-aisle chalk lines defining the edge of each frame line. Once you have this down and you know your layout will fit within your facility, you’ll want to erect a starter pallet rack bay.

(Image: unicor.gov)

Step 2: We recommend you start the erection of the starter bay by first marking the beam elevations on the frames, then standing the frames. This will make it easier to know you are installing the beams exactly as the system was designed.

Step 3: Once you have the first starter bay up, you’ll want to square, plumb, level, and anchor the bay. After this first bay is up and anchored into the floor, just repeat the process by attaching each adder bay to the end of the starter bay and working your way down the aisle.

The rest of the pallet rack row can be set up prior to anchoring.

Step 4: We recommend that you always anchor your pallet rack system, but we do want to acknowledge that some city codes suggest that anchoring may not be necessary for short (8’ or less) stable racks that are loaded and unloaded by hand.

Step 5: Install any accessories such as row spacers, wire decking, post protectors, or rack safety back panels. We recommend you install row spacers 12” from the top of the upright and 12” from the bottom of the pallet rack upright. Furthermore, you should initially install these loosely and then tighten them once the entire pallet rack row is completely installed, plumbed, and tightened.

You should consider how the post protectors need to be installed prior to anchoring your rack because some column protector styles require a common anchor bolt with the rack. Other types can be installed independently after your pallet rack system installation has been completed.

Accessories such as pallet supports or wire decking should be installed after the pallet rack uprights and pallet rack beams have been installed and all the anchor bolts have been tightened.

Please realize this is a general overview and we might have missed a step or a manufacturer recommendation, so always check the manufacturer’s instructions prior to installation.

Pallet Rack Maintenance

Once you have your pallet rack system installed, you’ll want to make sure you have a maintenance plan in place. In a warehouse, safety is the most important thing, and it’s no different when it comes to your pallet rack. Pallet racks will need to be checked regularly to make sure there are no problems. Sometimes poor installation can endanger employees, but more often employees driving forklifts will bump or run in to the uprights and beams.

Over time the damage sustained from these bumps can make your system incredibly dangerous. We, therefore, recommend you give your pallet rack system a thorough safety review once a year to look for damaged beams and uprights.

Pallet Rack Repair

Not all pallet rack damage is the same. Whether pallet rack damage can be fixed depends on the severity of the damage. Since most pallet rack damage is due to being struck by forklifts, the damage tends to be on the lower half of your pallet rack upright.

Trouble spots that likely need to be repaired include dents, cracks, bulges, pinched columns and missing braces. These are all signs that a forklift has collided with your pallet rack.

The best way to reduce damage is to stop it before it happens. You can do that by installing equipment designed to keep forklifts from striking your pallet rack.

End of Aisle Guard Racks provide low-profile protection for your pallet rack. They prevent forklift damage to the side and front of the rack.

Lift Out Guard Rail Posts also protect structural platforms like pallet rack. The lift out brackets are welded to the column, and it can prevent a 10,000-pound forklift from breaking through the posts at a 5 mph rating.

Post Protectors are meant to take the hit for your upright. They can easily be removed and replaced if hit by a forklift.

While pallet racks are known for their ability to keep warehouses organized, they also need to be installed and maintained correctly. As you decide on what pallet rack to buy, remember that experienced installers can get you started safely. And with regular inspections and the right safety products, your pallet rack can have a long and safe life.

Are you looking for a pallet rack system?

American Storage & Logistics has a full inventory of warehouse equipment and provides engineering, design, and consulting services for businesses. We have different pallet rack systems and can help you find exactly what you need. Reach out to us today, shop our catalog online, or give us a call at 866-323-8310!