Gravity conveyors utilize gravity to move products and materials. They are mostly used in assembly lines and picking operations at warehouses where materials need to be transported between different locations. Unlike other types of conveyor systems, gravity conveyors do not have a motor and therefore are less costly to operate and maintain.

Gravity conveyors can be installed at an incline or on a flat surface. At an incline, the rollers or wheels on the conveyor bed allow for the product the move down. If the conveyor is installed on a flat surface, workers need to manually slide products down the line. This is especially useful for assembly lines or workstations.

There are different types and configurations of gravity conveyors. If you are in the market for one, read on to learn more about the different features to consider when purchasing a gravity conveyor.

Different Types of Gravity Conveyors

A good place to start is to familiarize yourself with the different types of gravity conveyors so you can select the one that will work best for your business. There are three main types of gravity conveyors:

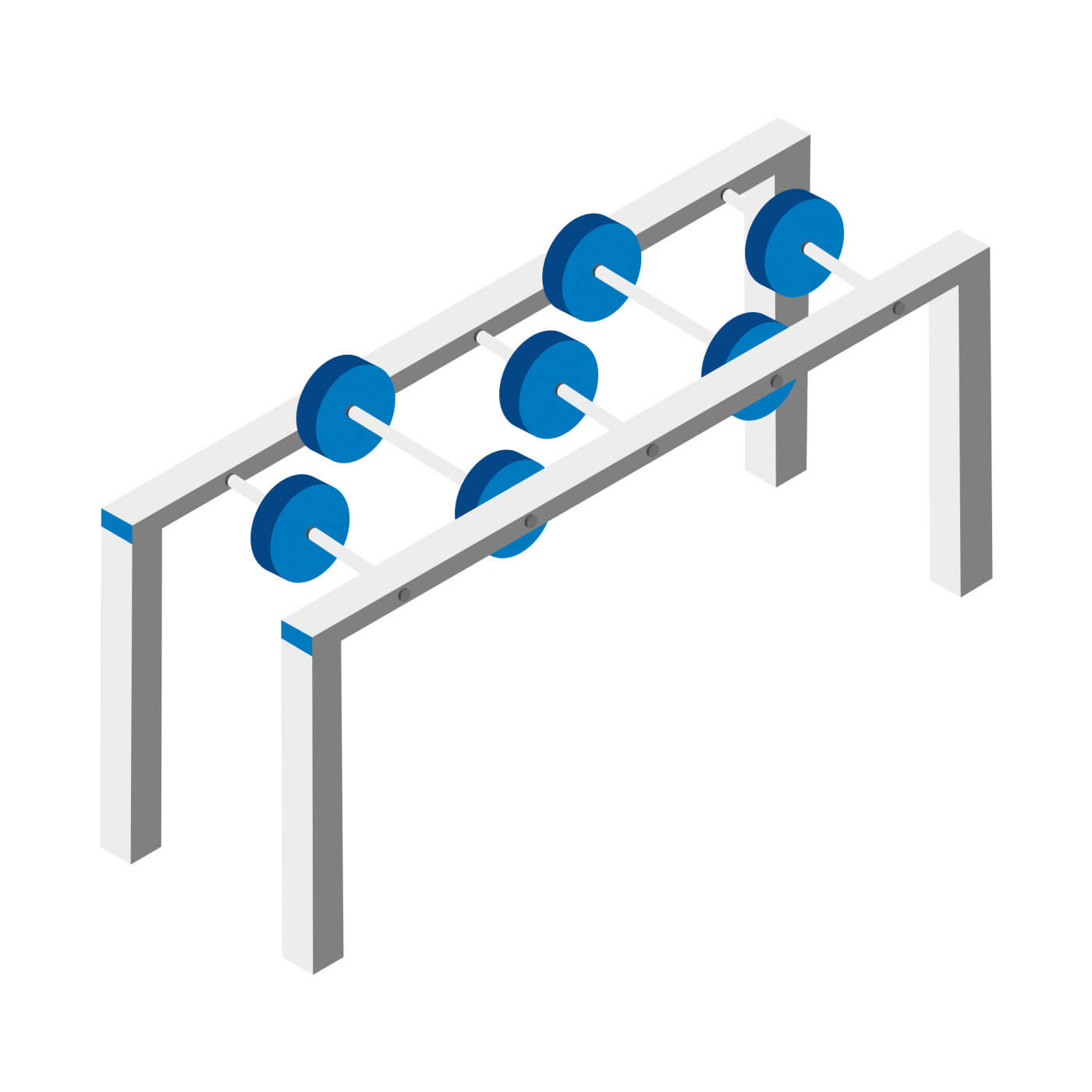

Skatewheel Conveyor

Skatewheel conveyors have small, round wheels on the conveyor bed that help move products. The wheels are often made out of plastic and are lighter duty.

Gravity Roller Conveyor

As the name suggests, gravity roller conveyors have rollers that move products. They are most commonly used to move cartons, pallets, and packages over short distances. There are various sizes of rollers available for different applications.

Expandable Gravity Conveyor

Expandable gravity conveyors give the user increased flexibility over the location and configuration of the conveyor. They are great for temporary use and applications that require mobility of the conveyor system. They also don’t require assembly and come in one piece; which makes the setup much easier. The legs of an expandable conveyor can be adjusted to different heights similar to other stands. The conveyor has swivel casters that are used to move the conveyor to different locations. The expandable conveyor also has many setup options such as in a straight line, zigzag, or circle.

Things to Consider Before Purchasing a Gravity Conveyor

Gravity conveyors are made up of several parts that can be purchased separately and put together to create a setup that works best for your operation. To learn more about the different parts and their installation, read this article. Here are a few things to consider when selecting parts:

Load Capacity & Type of Products

Consider the type of products or materials you will be moving on the conveyor. Skatewheel conveyors work best for lighter products that have smooth and even bottoms. This type would be a good fit for picking operations that use lighter cardboard boxes. Skatewheel conveyors are also more cost-effective than roller conveyors. If your products are consistently lighter and have even bottoms, this type would be a good choice.

If you are looking for a more heavy-duty option or have products with uneven shapes or containers with uneven bottoms, roller conveyors would be a better fit. Since the rollers have a larger surface area, they do a better job of being able to move different objects. They come in different load capacities. For heavier duty products, larger diameter rollers such as 2.5” or 3.5” are used. 1.5” diameter rollers will work for most lighter-duty (under 100 lbs.) products, whereas 1.9” rollers can move medium-weight loads that are over 100 lbs.

Section Size

Sections are what hold the roller or wheels together. You have the option to place the rollers or wheels closer together or further apart, depending on the size of the product. A good rule to remember is that there should be at least three rollers under the product at all times.

A lot of times gravity conveyor sections are sold in 5’ or 10’ sections. These sections are installed together to create a conveyor of the desired length. There are also curved sections that can be used to add turns to the conveyor. Purchasing standard-size sections is usually cheaper, and it’s easier to find other parts to match.

Frame Size

Conveyors have an exterior frame that holds the sections of wheels or rollers. Certain types of frames only work with certain types of sections. Another thing to consider is the width of the products you carry. Keep in mind that the rollers need to be longer than the size of the item they carry to ensure that products stay on the conveyor. Make sure to account for the largest items that you may use the conveyor for before deciding on the roller size and frame width. There are also optional side guides that can be purchased to keep items on the track.

Conveyor Supports

It’s very important to account for the maximum weight the conveyor will carry when selecting conveyor supports (conveyor stands). Supports come in many height and weight capacities. There are also portable and permanent supports. Permanent, stationary supports are anchored to the floor and can carry heavier loads.

Many times conveyor stands are also adjustable in height. This feature can be used to create a slope in either direction or to simply raise or lower the conveyor table.

Used or New

Another thing to consider when purchasing a gravity conveyor is whether to buy new or used. This is a very personal choice as both have their pros and cons. Used equipment can save you a lot of money, but ordering new parts gives you greater flexibility over options. New equipment also comes with more extensive warranties. All of our used gravity conveyor systems at American Storage and Logistics are inspected for dents, cuts, or excessive rust, and come with a 90-day warranty. To learn more about what to look out for when buying used equipment, check out our informative guide on the topic.

American Storage and Logistics Has All of Your Gravity Conveyor Needs

American Storage and Logistics has been a leader in new, used, and refurbished warehouse equipment for over 50 years. We have gravity conveyor parts in stock and we offer same-day pickup or next-day delivery to the mid-Michigan areas, including Grand Rapids, Lansing, Battle Creek, and Kalamazoo. Check out our selection of gravity conveyors on our website.

We also offer warehouse design services and would be happy to assist with the process of ordering and designing your gravity conveyor setup. Call us today at 866-678-0326 to speak with a sales engineer.