Forklifts are a quick and efficient way to transport pallets in a warehouse. They are an indispensable piece of warehouse equipment. However, they are also the leading cause of damage to palletized products and racks. Not to mention the injury that they can cause to warehouse workers. For this reason, improving forklift safety should be a priority of all warehouses.

OSHA estimates that 110,000 forklift accidents take place in the US every year. These accidents cost businesses more than $135,000,000 every year. Luckily, there are several pieces of equipment designed to prevent these damages and injuries and improve forklift safety at your warehouse. It’s a smart business move to invest in equipment to help reduce these incidents.

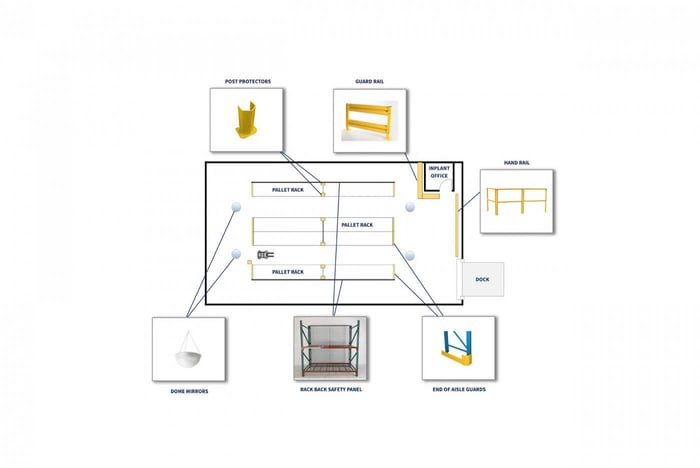

Here are the most common ways that forklifts cause injuries and damage warehouse equipment, and ways to prevent them:

Damage to Pallet Rack Uprights

Pallet rack uprights are often in danger of getting hit by a forklift. This usually happens during the process of picking up pallets from a rack and maneuvering to get out of the aisle. The driver is more likely to hit the rack behind them when backing up. Even the most careful driver can make this mistake in a fast-paced warehouse environment.

Post protectors prevent damage to the pallet rack uprights. They are installed directly on the pallet rack uprights to protect them from accidents.

New Polymer Snap-On Post Protector, 24"H, Fits 3"W x 1-5/8"D Columns, Yellow

$29.00

Post Protectors help protect your racking from forklift damage and other accidents in the warehouse. Fits on 3"W x 1-5/8"D upright columns Sold individually Snap-on post protectors can be installed by hand and require no tools or hardware Sold in bright, OSHA… read more

Another common way that pallet racks get hit is when a forklift driver turns too early when entering or exiting an aisle and hits the rack instead. Forklifts are rear-wheel drive, meaning that the direction is guided by the back wheels. This allows them to be able to operate in small radiuses. But there is a difference in the way the forklift operates when it has a pallet loaded onto the forks versus not. If the forklift is being driven without a pallet, the rear end may swing out a little and hit the rack closer to the back side.

Guard Rails are a great way to prevent the ends of aisles from forklift damage. They can also be installed around structural platforms, in-plant offices, conveyors, and building structures such as water mains.

18"H Bolt-On Guard Rail Column, for Single Rail, 4"W x 4"D, 10" sq. base plate

$104.90

Protection for structural platforms, in-plant offices, conveyors, water mains and other valuable equipment Easy installation. Includes 1 post with base 10,000 lb load at 5 mph rating Bright OSHA yellow finish Columns are 4" square high-strength steel tube Baseplate is… read more

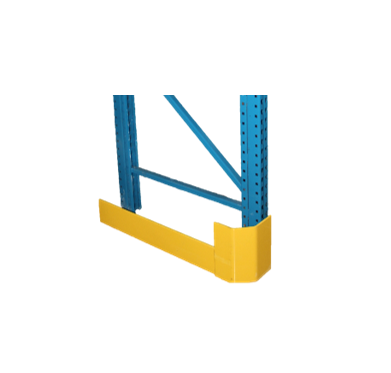

Aisle Guards are another way to protect pallet rack side and front from forklift damage. They are made specifically to go on the right or left side of pallet rack for low profile protection that doesn’t affect visibility.

New Pallet Rack Aisle Guard, 12"H x 45"L x 9.68"W, Floor-Mounted, Left Side

$104.49

Low profile, protection for pallet rack 12"H corners Fits 3"W pallet rack columns Prevents forklift damage to side and front of pallet rack Heavy duty, all-welded 1/4" thick steel Bright OSHA yellow finish Anchor bolts included If you would like… read more

Accidents Due to Obstructed View

Drivers not being able to see pedestrians and equipment in their way is a common cause of accidents in the warehouse. Furthermore, ramps and other sloped surfaces that are not marked clearly can cause the forklift to tip over. Like with any vehicle, a forklift has blind spots and limited visibility. To prevent these accidents, it is important to keep forklift lanes clear of debris and obstructions. But blind spots created by cross aisles and other obstructed areas may not be as easy to overcome.

Hanging mirrors are useful in increasing visibility at cross aisles and obstructed areas. The mirrors are hung from the ceiling to eliminate blind spots and danger areas. The dome shape of the mirror creates a 360-degree view for ultimate visibility. Hanging mirrors are great for any obstructed areas and high-traffic zones, and they can dramatically improve forklift safety in your warehouse. When purchasing a hanging mirror, a good rule of thumb to keep in mind is that every inch will allow you to see 1 foot of area. Determine the size of the area that you are wanting to increase the visibility of to see what size of mirror you need.

360 Degree Full Dome Acrylic Mirror, 36" Diameter, 36' Distance Covered

$178.30

Dome mirrors eliminate blind spots and danger areas found in most industrial and warehouse settings. 36" Diameter Perfect for any high-traffic area Lightweight, Grade A optical acrylic for crisp, clear reflection Comes standard with hanging hardware 360 degree view Can… read more

Accidents Caused by Improper Floor Markings

Improper or missing floor markings lead to accidents between forklifts and pedestrians. It is important to have clearly marked aisles and lanes for pedestrians and motorized equipment to travel in.

Safety bollards are used to create a visual barrier and to physically keep vehicles out of the way of people and building elements. They are also a great way to protect other equipment from getting hit by forklifts.

40"H x 6" Diameter, Standard Duty Surface Mounted Bollard

$116.10

Excellent for separating vehicles from people Protects dock doorways and building passages 6" diameter schedule 10 tubing, standard duty Fill with cement for additional impact resistance Bright OSHA yellow finish Surface mount design (1/2" x 5" screws included) If you… read more

To create a safe zone in your warehouse, first, identify areas where forklifts should not be operated. Then, use bollards to create borders around those areas. You can also place bollards in front of building elements such as electrical boxes to prevent accidental damage.

Safety Tips for Operating a Forklift

-

Forklifts should only be operated by trained and certified personnel.

-

Make sure to regularly check and maintain your forklift. Do not operate it if it’s in need of repair.

-

Do not exceed the recommended weight load and make sure that the load is secure before attempting to move.

-

Make sure that the forklift is in a parked position when raising or lowering the load, do not make adjustments during travel.

-

Ensure that you have clear visibility of the work area and give yourself enough clearance from aisles, platforms, and ramp edges.

For additional safety tips to get your warehouse to OSHA Standards, check out our article Warehouse Safety Checklist.

Pallet Jack: Another Option for Transporting Pallets

Forklifts are convenient to use and may be the best option to move pallets over a certain weight. But for lighter duty operations, safer alternatives exist. Pallet jack is another piece of equipment used to transport palletized goods. They come in manual and motorized models and do not require a license to operate. They are a simpler and safer alternative to a forklift, with less chance of accidents and damage to equipment. Pallet jack can be used in place of a forklift as long as the pallets you move are within the weight limit and you don’t need to lift them up to high shelves. The average pallet jack can typically carry 5,000 lbs, and lift pallets a maximum of 8 ft. Although they can’t lift as heavy loads as a forklift, pallet jacks are great for lower-duty lifting tasks. They are also more cost-effective and smaller than forklifts, making them easy to operate in smaller spaces.

American Storage and Logistics Has All of Your Warehouse Safety Needs

American Storage and Logistics has been the leader in new, used, and refurbished warehouse equipment for over 50 years. We have a large online selection of warehouse safety equipment, in-stock and ready to ship the next day. We offer same-day pickup or next-day delivery to the mid-Michigan areas, including Grand Rapids, Lansing, Battle Creek, and Kalamazoo.