The increased demand for eCommerce and the lack of available warehousing space has led businesses to look for more efficient ways to store inventory. Utilizing high-density storage solutions such as a drive-in racking system is one way to improve your storage efficiency without having to increase your warehouse space.

A drive-in pallet rack system is created by arranging pallet rack back to back. This formation allows pallets to be stored multiple positions deep. Drive-in racking eliminates the use of aisles and only has one access point. Although this storage system was more popular in cold storage and freezers with very limited space, it has become a popular way to arrange pallet rack in other warehousing facilities as well. One of the biggest advantages of using a drive-in racking system is that it can accommodate 75% more pallets than regular racks can.

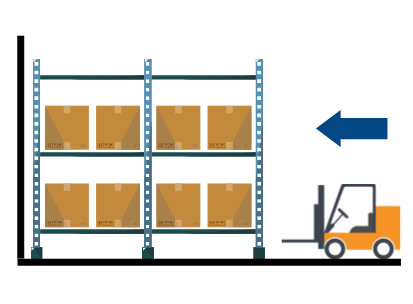

A Drive-In Racking System Uses Last In First Out (LIFO) Rotation

In a drive-in system, forklifts are used to load and unload the pallets in a LIFO (Last In First Out) rotation. The pallets are loaded at the access point, where workers slide newer products in front of the older ones. During retrieval, the products in the front are taken first, which were the last to be loaded. LIFO is not suited for time-sensitive products or those that require stock rotation but works great for products that don’t have shelf-life constraints.

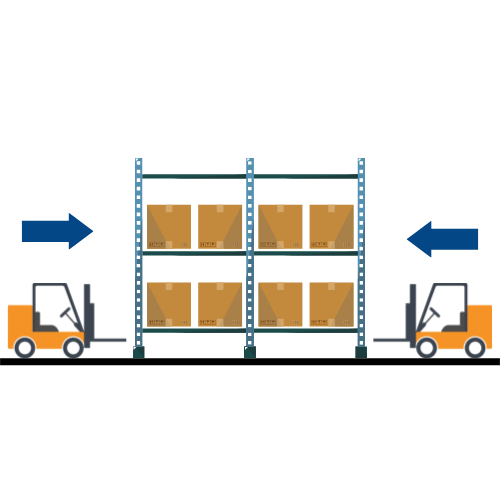

Businesses looking to implement a higher density storage system without having to use LIFO rotation can consider drive-through racking. Drive-through racking is similar to drive-in but has two access points; one for loading and one for unloading. This system allows for FIFO (First In First Out) where the first loaded products are the first to be retrieved.

Drive-In Racking System

Drive-Through Racking System

Advantages of Drive-In Racking Systems

Drive-in racking systems offer many advantages. Here are some of the main benefits of using a drive-in system:

- Drive-In Racking Increases Storage Space & Density

If you are tight on warehouse space and need to create a more efficient way to store inventory, a drive-in racking system may be a good fit for you. Facilities with a large volume of products and high turnover benefit the most from a drive-in system.

- Can Be Placed Against a Wall

Since drive-in systems only need one access point, the rack can be placed against a wall or a corner, which helps maximize space in your warehouse. If you need two access points, a drive-through system may be a better option. Also, if your needs change, a drive-in system can be converted into a drive-through system.

- Cost-Effective

Drive-in racking costs less than most other racking systems and allows for more efficient storage. Because of how cost-effective it is, drive-in racking is becoming more popular outside of cold storage where it’s been most commonly used.

Disadvantages of Drive-In Racking Systems

A drive-in racking system is not suitable for all warehouses. Here are some of the reasons why you may want to look at other racking systems:

- Drive-In Racking Only Allows for a Small Variety of Products

Since the products are packed very tightly in a drive-in racking system, it would be very difficult to access and retrieve multiple SKUs of products. Therefore it works best for warehouses with a small variety of products.

- Can Only Be Used with the LIFO Rotation

As mentioned earlier, a drive-in rack requires the use of the LIFO method to load and retrieve products from the rack. If you prefer to use the FIFO method, you can look into drive-through racking which still offers high-density cost-effective storage.

- Not Ideal for Storing Seasonal Products or Products with Short Shelf Life

Because the products stored in a drive-in system are not retrieved in the order they were loaded, it is not ideal for storing time-sensitive products.

In summary, a drive-in racking system is an easy to implement and cost-effective high-density storage that is worth considering for warehouses that are tight on space. It is ideal for high-volume operations that only carry a low variety of SKUs, and works great for warehouses that experience sudden influxes of inventory that quickly moves in and out.

American Storage and Logistics Has All of Your Pallet Rack Needs

American Storage and Logistics has been helping warehouse owners maximize efficiency with cost-effective solutions for over 50 years. We have our entire in-stock inventory online on our website, ready for next business day pickup or shipping. If you need help with your order, please call 866-690-5392 to speak with one of our sales engineers. We also offer warehouse design services; click here to learn more.